In today’s fast-paced world of customized production, the impresión UV machine has become a game-changer for manufacturers, designers, and entrepreneurs who need high-quality printing on demand. Whether you are producing signage, promotional gifts, decorative panels, or industrial components, a UV printer allows you to print vivid, durable images directly onto almost any surface — with incredible precision and speed.

What Is a UV Printing Machine?

A UV printing machine (also known as a UV flatbed printer) uses UV-curable ink and ultraviolet LED lamps to instantly cure the ink as it’s printed. Unlike traditional printing methods that rely on heat or solvent drying, UV printing technology uses ultraviolet light to harden the ink, forming a thin, durable film on the material surface.

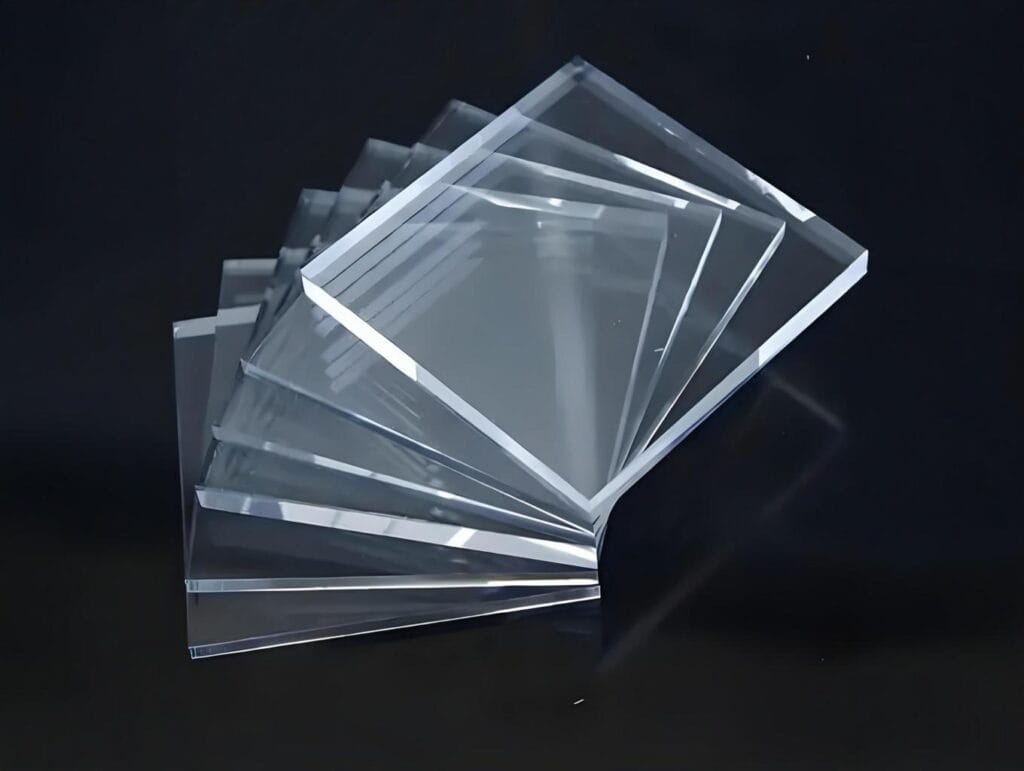

This process allows printing on a wide variety of materials, including glass, wood, acrylic, PVC, metal, leather, ceramic tiles, and more. In short — if the surface fits into the printer, it can be printed.

Why Choose a UV Printer?

Versatility Across Materials

One of the biggest advantages of a UV printer is its compatibility with nearly any substrate. From advertising signs to phone cases, from packaging boxes to wooden decor panels — a single UV printing machine can handle them all.

For cylindrical or irregular objects, many UV flatbed printers can be equipped with rotary attachments, allowing precise printing on bottles, mugs, or tubes.Brilliant and Long-Lasting Colors

UV printing produces extremely sharp and vibrant results. Using CMYK + white ink + varnish, users can achieve high-gloss, matte, or even 3D embossed effects — all directly from the printer. The cured UV ink is resistant to scratching, moisture, and sunlight, making it ideal for both indoor and outdoor use.Eco-Friendly and Energy Efficient

Modern UV printing machines use LED UV lamps instead of traditional mercury lamps. This means lower power consumption, no ozone emissions, and longer lamp lifespan. Additionally, UV inks are solvent-free and produce minimal odor, contributing to a greener printing environment.Simple Operation and Low Maintenance

With intelligent software and automated ink control systems, even non-technical operators can easily manage production. The maintenance cost is lower compared to traditional printing, and there’s no need for complicated setup or plate-making.

Applications of UV Printing Technology

The UV printing machine is widely used across various industries due to its flexibility and cost efficiency. Common applications include:

Advertising and Signage – banners, acrylic displays, foam boards, and LED sign panels

Home Decoration – custom wall panels, wooden doors, glass backgrounds, and floor tiles

Electronics and Accessories – mobile phone cases, control panels, power banks, and laptop shells

Gifts and Crafts – photo frames, trophies, souvenirs, and packaging boxes

Industrial Printing – instrument panels, product labels, nameplates, and prototypes

Whether for mass production or personalized customization, the UV printer delivers both artistic creativity and industrial reliability.

The Future of UV Printing Machines

As technology continues to advance, UV printing machines are becoming faster, smarter, and more versatile. New-generation models feature:

Multi-printhead configurations for higher productivity

Advanced color management and RIP software

White ink circulation systems to prevent clogging

IoT remote monitoring for real-time maintenance and updates

Enhanced 3D printing and spot varnish effects

These innovations make UV printing technology an essential part of digital manufacturing — bridging the gap between creativity and industrial production.

How to Choose the Right UV Flatbed Printer

When choosing a UV printing machine, consider your business type and production needs:

For large-format signage: Choose a wide-format UV flatbed printer with a stable platform.

For small customized products: A desktop A3 or A2 UV printer is ideal for flexibility and small-batch printing.

For bottles and round objects: Ensure the machine supports rotary printing.

For premium results: Look for a printer with varnish and embossing (3D) capabilities.

It’s also crucial to choose a reliable UV printer manufacturer with strong technical support and spare parts availability. A good supplier not only provides the machine but also offers ongoing training, color management solutions, and after-sales service — ensuring stable, long-term operation.

The UV printing machine is not just a piece of equipment — it’s a bridge that connects design ideas with real-world products. With its instant curing, vibrant colors, and material versatility, UV printing technology is redefining how businesses approach customization and digital production.

As demand for personalized and eco-friendly products continues to grow, UV printers will play an even more important role in the global printing industry. Choosing the right machine today means staying ahead of your competition tomorrow.