In the rapidly evolving landscape of global manufacturing, Impresión UV is no longer just about depositing ink—it represents the future of product customization and on-demand production. From glass and metal to leather and ceramics, UV printing is rapidly replacing traditional methods with its instant curing, stunning durability, and eco-friendly features. This article dives into the principles and application benefits of UV printing, and details how cutting-edge equipment like the Beric UV Printer can help businesses maintain a strong competitive edge in the global export market.

I. What is UV Printing? A Brief Overview of the Principle

UV printing, short for Ultraviolet-curable Inkjet Printing, gets its core strength from its unique curing process.

Unlike traditional inks that require air or heat drying, UV printers use special liquid photo-sensitive inks. Once these inks are jetted onto the substrate surface, they are immediately exposed to high-intensity ultraviolet light (UV-LED). This UV light instantly triggers a polymerization reaction in the photoinitiators within the ink, instantly transforming the liquid ink into a solid, durable polymer film.

Key Advantages:

- Instant Curing: Prints are dry almost the moment they leave the print head, eliminating waiting time and drastically increasing production speed.

- Non-Porous Versatility: The ink cures on the surface of the material without being absorbed. This is what enables UV printing on virtually any non-absorbent medium, including glass, metal, plastics, and wood.

II. Why is UV Printing the Future of Manufacturing?

UV printing is experiencing explosive growth in global trade and industrial production because its benefits extend far beyond speed and versatility.

1. Unmatched Material Compatibility and Versatility (Substrate Diversity)

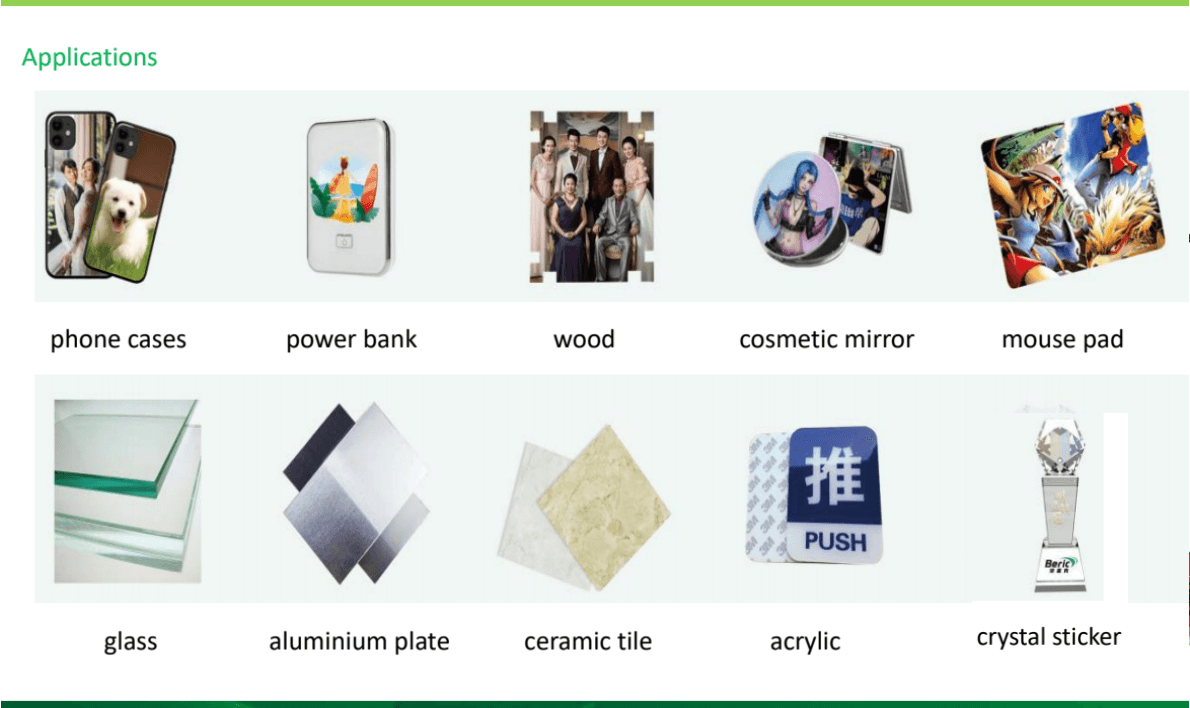

Traditional printing methods are often limited by the absorbency of the material. UV printing, however, can print on almost anything:

- Rigid Materials: Acrylic, glass, tiles, stone, metal sheets, wood, PVC.

- Flexible Materials: TPU phone cases, leather, canvas, soft film ceilings, and vinyl.

This “one machine, multiple functions” capability significantly reduces a company’s equipment investment costs and broadens the potential product range, especially in high-margin sectors like custom gifts, industrial signage, and architectural décor.

2. Superior Durability and Longevity

The ink layer, once UV-cured, possesses strong physical and chemical properties:

- Scratch and Abrasion Resistance: The cured ink layer is hard, durable, and not easily worn down by daily use.

- Weather and UV Resistance: UV inks resist the sun’s ultraviolet rays and harsh weather conditions, keeping colors vibrant and resisting fading, making them perfect for outdoor applications and long-term industrial use.

- Waterproof and Chemical Resistance: This makes it suitable for applications such as medical devices, automotive parts (like the fuel pumps previously discussed), and industrial machine panels that require resistance to cleaners and chemicals.

3. Enhanced Environmental Safety (Eco-Friendly)

UV inks fall into the category of low VOC (Volatile Organic Compounds) or even zero VOC formulations.

- Solvent-Free: This avoids the release of large amounts of harmful gases that solvent-based inks typically emit during the drying process. This improves the factory’s working environment and complies with increasingly strict international environmental standards.

- Reduced Waste: Instant curing minimizes scrap rates and rework, leading to higher material utilization.

III. Beric UV Printer: Crafting Your Global Customization Solution

With the surging demand for reliable UV printers, choosing high-quality, efficient equipment is critical. The Beric UV Printer has become an ideal choice for global trade and industrial clients, leveraging its technical expertise and customization capabilities in the UV Printing field.

1. Beric UV Printer’s Core Technical Advantages

The Beric UV Printer is engineered for industrial stability and high precision, making it more than just a piece of equipment:

- High-Precision Printhead System: Beric printers are typically equipped with the latest industrial-grade printheads, ensuring extremely high resolution and fine droplet control, even during fast printing. This guarantees image clarity and smooth color gradients.

- White Ink Circulation System: White ink is crucial in UV printing for creating an opaque base layer on dark or transparent materials. Beric’s automatic circulation and agitation system effectively prevents white pigment settling and clogging the printheads, ensuring the consistency and stability of your UV Printing workflow.

- Simultaneous Multi-Layer Printing Technology: This advanced feature allows the Beric UV Printer to print stacked effects like Color-White-Varnish in a single pass. This achieves embossed or 3D tactile effects, significantly increasing product added value and customization depth—a key differentiator in high-end markets.

2. How Beric Helps Export Businesses Capture Market Share

For businesses focused on foreign trade, choosing a Beric UV Printer provides distinct advantages:

- On-Demand Production: Customers can order small batches or even single customized units, eliminating inventory buildup and perfectly aligning with the current “zero inventory” trend.

- Rapid Prototyping and Delivery: The instantaneous curing characteristic significantly shortens the time required for prototyping and final product delivery, helping your business win time in the global competition.

- International Compliance: Beric equipment is typically designed and manufactured to meet strict international safety and quality standards, ensuring your products can smoothly enter high-standard markets like Europe and North America.

IV. The Future Trends of UV Printing: Intelligence and Integration

UV printing technology continues to evolve rapidly. Future trends will primarily focus on the following areas:

- AI-Driven Automation: Future UV Printing systems will integrate more sensors and AI algorithms to automatically perform printhead calibration, ink droplet compensation, and color management, leading to less operator intervention and higher efficiency.

- Broader Integrated Applications: UV printing will be more closely integrated into automated production lines, becoming a part of Industry 4.0, for example, performing real-time labeling and serialization during the final stages of product assembly.

- Sustainability: Ink chemistry will continue to evolve, focusing on developing more eco-friendly and energy-efficient UV curing systems to further reduce environmental impact.

UV Printing technology has cemented its core position in modern manufacturing due to its near-limitless adaptability to materials, superior durability, and rapid production cycles. Selecting a machine with advanced technology and stable performance, such as the Beric UV Printer, is crucial for maintaining your competitive edge in the global customization wave. The time to invest in UV printing technology and illuminate your path to product innovation is now.