Unveiling the Power of UV Gloss Printing

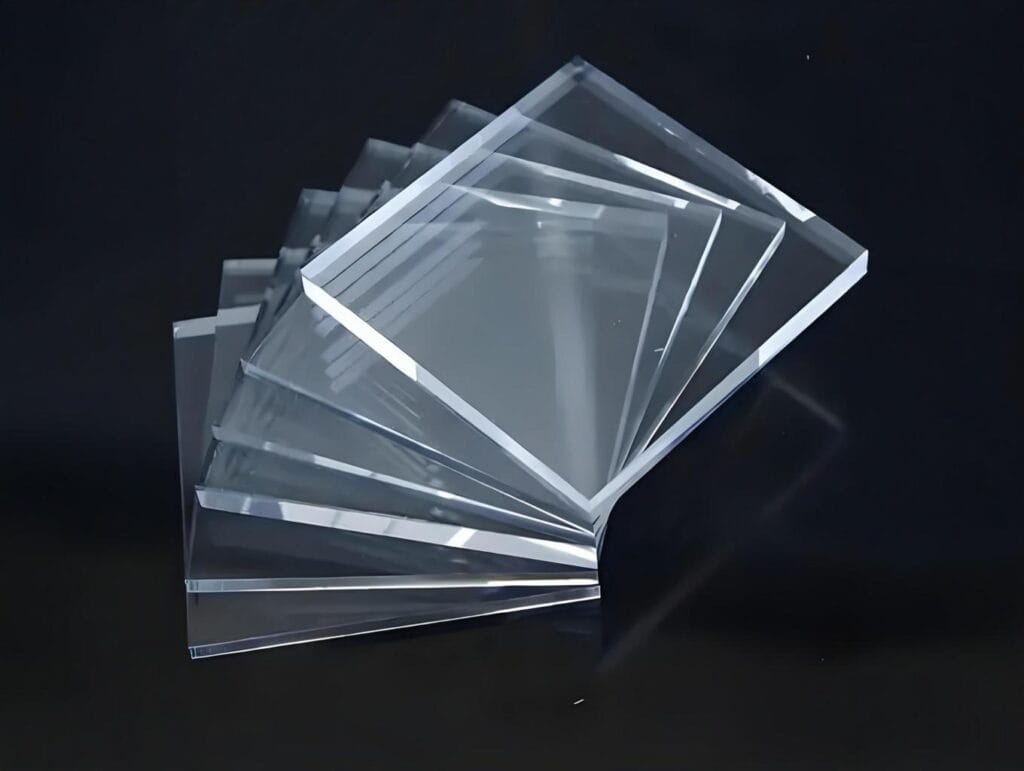

UV printing technology has opened up new possibilities in the printing industry, making it easier than ever to produce visually captivating and durable prints. Among its many advantages, one of the most impressive is the ability to deliver outstanding gloss effects. Unlike traditional printing methods that rely on coatings or laminations, UV printers can directly print a glossy finish onto a wide range of surfaces. This not only elevates the look of the product but also ensures added protection against scratches, moisture, and fading.

For industries such as packaging, signage, marketing, and custom design, the gloss finish is a game-changer. It transforms ordinary prints into premium products that catch the eye immediately. The crispness, brightness, and depth provided by UV gloss printing can make even simple designs look luxurious and professional.

How UV Gloss Printing Works

The key to UV gloss printing lies in its use of UV-curable inks. These inks are exposed to ultraviolet light immediately after being applied, causing them to harden and cure instantly. This process creates a glossy surface that is both smooth and resilient. Unlike conventional drying methods, there is no waiting time, no smudging, and no compromise on detail.

Another advantage is versatility. UV printers can apply gloss effects selectively, allowing businesses to create spot gloss designs where only specific areas are highlighted. This is perfect for emphasizing logos, images, or text, giving them a standout look without overwhelming the entire print. Moreover, UV printing works across different substrates—paper, plastic, leather, wood, and even metal—offering limitless creative possibilities.

Why Businesses Should Embrace UV Gloss Printing

In today’s competitive market, presentation matters more than ever. A glossy finish can make your marketing materials, packaging, or artwork stand out, creating a lasting impression on customers. For brands that want to project professionalism and quality, UV gloss printing is an investment that pays off.

It also helps reduce costs in the long run. Since the gloss effect is integrated directly into the print, there is no need for additional lamination or coating processes. This streamlines production, saves time, and minimizes material waste—all while delivering a premium product.

Conclusion

The power of UV gloss printing lies in its ability to combine beauty with durability. From luxury packaging to eye-catching business cards and from promotional brochures to creative artworks, UV printers provide unmatched quality and efficiency. If you want to elevate your prints and stand out from the competition, investing in UV gloss printing is the way forward.