When it comes to printing technologies, two main types often come up for discussion: UV printers and traditional printers. Both have distinct features and advantages, and understanding the differences between them can help businesses choose the right solution for their needs. In this blog post, we’ll explore the key differences between UV printing and traditional printing, examining everything from the printing process and materials to the quality and cost-effectiveness.

¿Qué es la impresión UV?

UV printing, or Ultraviolet printing, uses UV light to cure or dry the ink as it is printed onto a substrate. UV inks are specially formulated to dry almost instantly when exposed to UV light, which allows for faster production times and superior durability. This technology can be used on a wide range of materials, including non-porous surfaces like plastic, metal, glass, and wood.

UV printers are typically digital, meaning they work directly from a digital image file and apply ink directly to the surface. The UV light quickly hardens the ink, ensuring vibrant, high-quality prints that are both scratch-resistant and long-lasting.

What is Traditional Printing?

Traditional printing, which encompasses several methods like offset printing, screen printing, and inkjet printing, uses different mechanisms to transfer ink onto paper, fabric, or other substrates. These printing methods rely on a combination of heat, pressure, or solvent-based drying to set the ink. Traditional printers generally have more limitations in terms of material compatibility and color vibrancy.

Offset Printing: This is one of the most widely used methods for printing high-volume materials like books, magazines, and newspapers. Ink is transferred from a metal plate onto a rubber blanket, which then transfers the ink onto the printing surface.

Screen Printing: Typically used for printing on textiles, promotional products, and signage, screen printing uses a mesh screen to transfer ink onto the surface of the material.

Inkjet Printing: Commonly used in home and office settings, inkjet printers use liquid ink sprayed onto paper through tiny nozzles. These are great for printing documents, photographs, and simple designs.

Key Differences Between UV Printers and Traditional Printers

1. Printing Process

The primary difference between UV printers and traditional printers lies in the printing process.

UV Printers: These printers use ultraviolet light to cure the ink as it is printed. The ink is applied in liquid form, and the UV light hardens it immediately, ensuring that the print dries quickly and is ready for handling right away. The UV printing process can produce extremely high-quality, durable prints on a variety of materials.

Traditional Printers: Traditional printing methods, like offset and inkjet, typically rely on heat, air drying, or evaporation to set the ink. This can take longer than impresión UV, and the ink may be more prone to smudging or fading over time. The drying time in traditional printing can vary depending on the method, and certain materials may require additional drying or coating processes.

2. Materials Compatibility

One of the biggest advantages of UV printing over traditional printing is the range of materials that can be printed on.

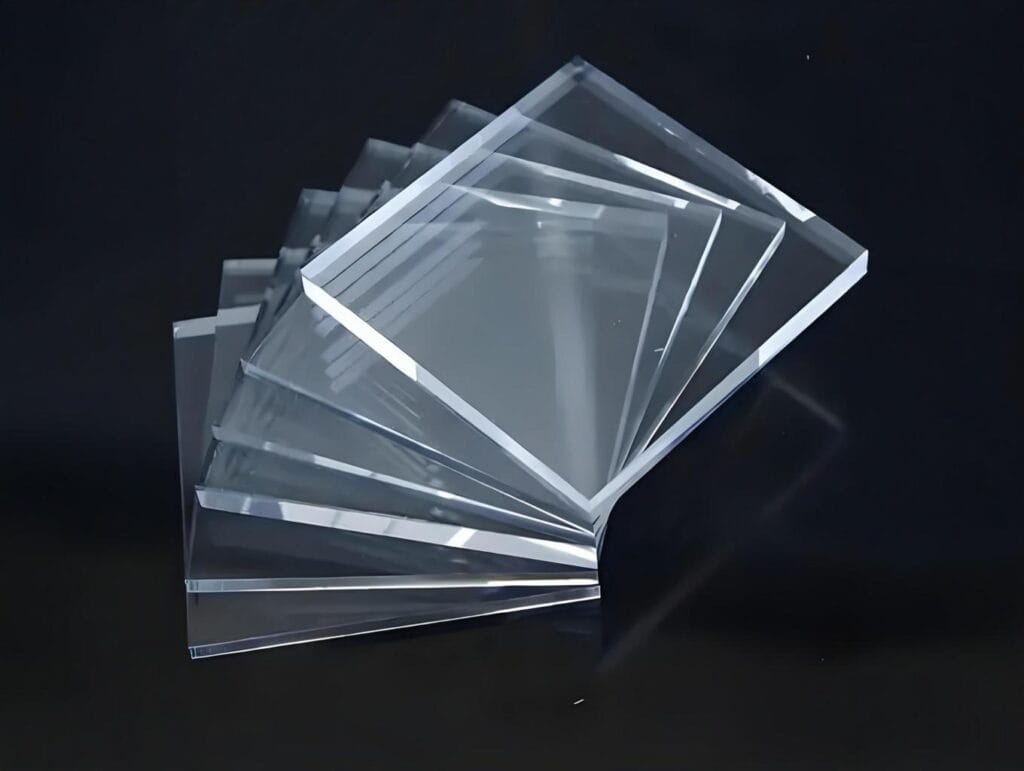

UV Printers: UV printers are incredibly versatile and can print on a wide variety of materials, including plastics, metals, glass, wood, acrylics, ceramics, textiles, and more. UV printing is ideal for printing on non-porous and rigid materials, and it can produce vibrant prints even on surfaces that traditional printing methods struggle with.

Traditional Printers: Traditional printers, especially inkjet and offset, are generally limited to printing on paper and certain textiles. While screen printing can be used for promotional items, it typically requires the material to have a specific texture or coating for the ink to adhere properly. These printers are not suitable for printing on non-porous or unconventional materials, which can restrict their flexibility.

3. Print Quality and Durability

When it comes to print quality and durability, UV printing has a clear advantage, especially for projects that require high resistance to wear and tear.

UV Printers: UV prints are known for their vibrant colors, sharp details, and long-lasting durability. The UV-curing process produces prints that are scratch-resistant, smudge-proof, and fade-resistant. This makes UV printing ideal for outdoor signage, promotional materials, and products that will be exposed to wear and tear.

Traditional Printers: While traditional printers, such as inkjet printers, can produce high-quality prints on paper and other surfaces, the prints are generally more susceptible to fading, scratching, or smudging over time. Offset and screen printing can produce excellent results on specific materials, but the durability of the print can be less than that of UV prints, especially when exposed to moisture or sunlight.

4. Speed and Efficiency

The speed and efficiency of printing is another area where UV printing outshines traditional methods, particularly for custom and on-demand printing.

UV Printers: UV printers offer faster drying times because the ink is instantly cured under UV light. This allows for quicker production turnaround, and the prints can be handled immediately after printing. The ability to print on multiple materials without waiting for ink to dry also speeds up the process, making UV printers ideal for short runs and custom printing.

Traditional Printers: Traditional printing methods generally require more time for drying or curing. Offset printing, for example, can take longer due to the multi-step process of transferring ink to a substrate. Screen printing requires setting up screens for each color, which can be time-consuming, and inkjet printing may require longer drying times for larger prints or specific paper types.

5. Cost of Equipment and Maintenance

Both UV printing and traditional printing come with their own set of costs, including initial investment and ongoing maintenance.

UV Printers: The initial investment for a UV printer can be higher compared to traditional printers, as they require specialized technology, including UV lamps for curing. However, the overall operating costs can be lower because UV printers typically use less ink, require fewer setup steps, and are capable of printing on a wide range of materials without needing additional equipment or inks.

Traditional Printers: Traditional printers, especially inkjet and offset, have a lower initial cost for entry-level models. However, depending on the volume of printing, the cost of ink, paper, and other consumables can add up over time. In addition, traditional printing methods often require more setup time and maintenance, particularly for large runs or specialized printing tasks.

6. Environmental Impact

When it comes to the environmental impact, UV printing tends to be more eco-friendly than some traditional methods.

UV Printers: UV printing uses UV-curable inks, which emit fewer volatile organic compounds (VOCs) than traditional solvent-based inks. This makes UV printing a more environmentally friendly option, especially for businesses looking to reduce their carbon footprint. UV printers also use less energy in the printing process compared to traditional offset printing presses.

Traditional Printers: Traditional printing methods, particularly those using solvent-based inks, can emit higher levels of VOCs, which contribute to air pollution. Offset printing also requires the use of chemicals for cleaning and press maintenance, which can have environmental impacts if not disposed of properly.

In summary, UV printers offer several advantages over traditional printers, particularly in terms of material versatility, print quality, durability, and efficiency. While traditional printing methods still have their place in certain industries, UV printing has emerged as a highly effective solution for custom, high-quality, and durable prints on a wide variety of materials.

For businesses that require fast turnaround times, vibrant prints, and the ability to print on non-porous or unconventional surfaces, UV printers are the clear choice. They provide greater flexibility and are more suitable for high-end, custom printing applications, including signage, promotional products, and industrial printing.

Choosing the right printer ultimately depends on the needs of your business. If you’re working with a variety of materials and need to produce prints that can withstand wear and tear, a UV printer is likely the best investment. However, for large-volume projects that require cost-effective solutions on paper or standard textiles, traditional printing methods like offset or inkjet may still be appropriate.

Understanding the differences between UV and traditional printers will help you make an informed decision, ensuring that you get the best results for your specific printing requirements.