In today’s fast-evolving printing industry, UV printing has become one of the most advanced and versatile digital printing technologies available. Whether you are in advertising, packaging, or home décor, UV printing provides unmatched quality, flexibility, and durability. It allows businesses to print directly onto almost any material, bringing creative ideas to life with exceptional precision and color depth.

What Is UV Printing?

UV printing (short for Ultraviolet printing) is a modern digital printing process that uses UV-curable inks and ultraviolet light to instantly cure or dry the ink as it’s printed.

Unlike traditional printing methods that rely on heat or solvent evaporation, UV printing technology uses ultraviolet LED lamps to solidify the ink immediately on the material surface.

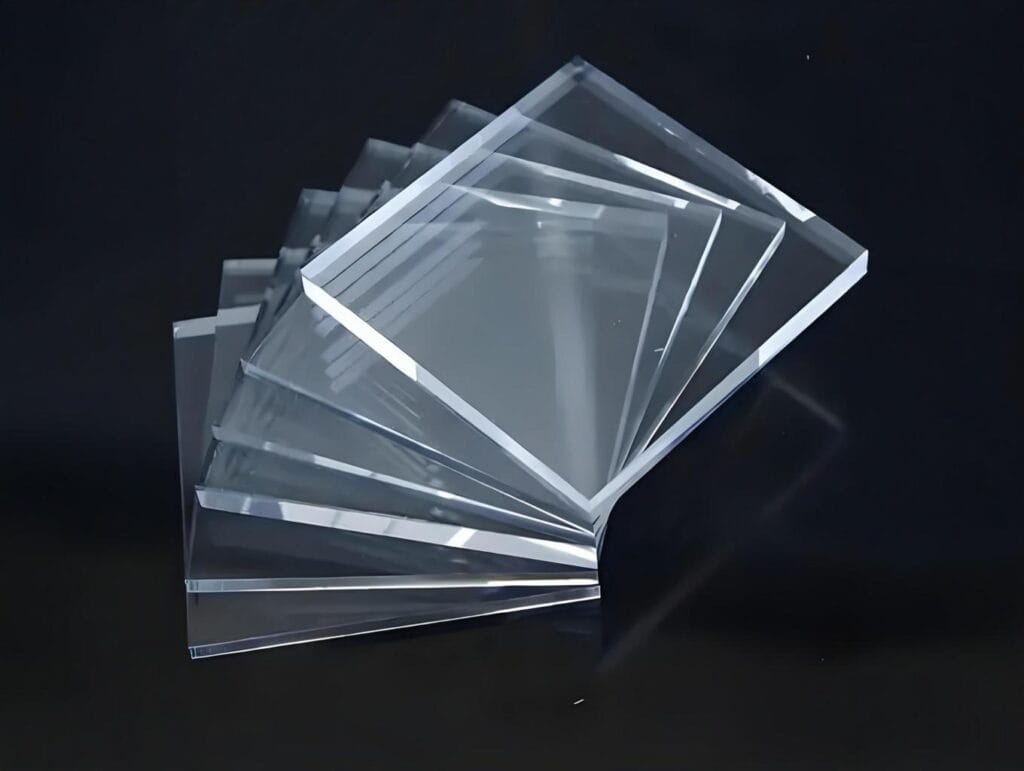

This instant curing process creates a durable, vibrant image that adheres strongly to various surfaces such as wood, glass, acrylic, metal, plastic, and leather. Essentially, if the object fits on the printer bed, UV printing can handle it.

How Does UV Printing Work?

A UV printer (or UV printing machine) works by spraying specially formulated UV ink directly onto a surface. As soon as the ink is deposited, UV LED lights follow closely behind, curing the ink through photochemical reactions.

This means:

No drying time

No smudging

No waiting for solvent evaporation

The result is a sharp, colorful, and durable image that’s ready to use immediately after printing.

Key Advantages of UV Printing

1. Print on Almost Any Material

One of the biggest benefits of UV printing is its incredible material versatility. From rigid substrates like wood, glass, and metal to flexible materials like leather and PVC, a UV flatbed printer can handle them all.

You can even print on cylindrical or curved objects using a rotary attachment — making UV printing perfect for bottles, mugs, and custom packaging.

2. Outstanding Color and Texture

UV printing technology supports CMYK + white + varnish inks, which allows for:

Rich, vibrant colors

Matte or glossy finishes

3D textured or embossed effects

This makes it ideal for high-end applications such as promotional items, decorative panels, and luxury packaging.

3. Instant Curing and Faster Production

Since the ink dries instantly under UV light, there’s no need for post-processing. Manufacturers can print, package, and ship on the same day — a huge advantage for short-run and on-demand production.

4. Eco-Friendly Printing Solution

Modern UV printers use LED UV lamps, which are energy-efficient, mercury-free, and produce no ozone. UV inks are low in volatile organic compounds (VOCs), making UV printing an environmentally friendly alternative to solvent-based printing.

5. Durable and Long-Lasting Results

UV-cured inks are resistant to scratches, moisture, and sunlight. This makes UV printed products suitable for both indoor and outdoor applications — from signage and displays to product labels and decorative art.

Applications of UV Printing

The versatility of UV printing makes it an ideal choice for a wide range of industries:

Advertising & Signage: Posters, boards, LED displays, acrylic signs

Home & Interior Décor: Wall panels, glass doors, custom furniture, ceramic tiles

Electronics & Accessories: Phone cases, control panels, device casings

Packaging & Labeling: Boxes, bottles, and custom packaging designs

Gifts & Crafts: Photo albums, awards, souvenirs, and personalized gifts

With its ability to print directly on finished products, UV printing eliminates the need for labels, stickers, or additional coating steps.

UV Printing vs. Traditional Printing

| Feature | UV Printing | Traditional Printing |

|---|---|---|

| Ink Drying | Instant via UV light | Air or heat drying |

| Materials Supported | Almost any surface | Limited to paper or coated materials |

| Environmental Impact | Low VOCs, no solvent fumes | High solvent use |

| Print Quality | High-resolution, vibrant colors | May fade or blur over time |

| Production Speed | Immediate output | Requires drying time |

Clearly, UV printing technology provides significant advantages in both performance and sustainability.

The Future of UV Printing Technology

As digital manufacturing and customization continue to grow, UV printing is evolving to meet new demands.

Modern UV printers now feature:

Multi-head configurations for faster production

White ink recirculation systems to prevent clogging

Advanced color management software

IoT remote monitoring and maintenance features

Future UV printing systems will be even smarter — integrating with automation lines and AI-driven production workflows. For manufacturers and printing businesses, investing in UV printing machines is no longer just an upgrade — it’s a strategic move toward digital transformation.

Choosing the Right UV Printer

When selecting a UV printer, consider:

Print size: Large flatbed vs. desktop models

Production volume: Single-head vs. multi-head systems

Material compatibility: Flat vs. cylindrical printing

Special effects: White ink, varnish, or 3D emboss options

Working with a professional UV printing machine manufacturer ensures reliable performance, consistent print quality, and responsive technical support. A trusted supplier will help you find the right model for your business needs and provide long-term service and training.

UV printing is more than just a printing method — it’s a revolution in how we produce customized, high-quality designs on demand.

With its instant curing process, eco-friendly operation, and outstanding versatility, UV printing technology is transforming industries from advertising to manufacturing.

As the global demand for personalization and sustainable solutions increases, UV printing will continue to lead the way — enabling faster, cleaner, and more creative production than ever before.