Printing on flat materials is easy, but many products in daily life are not flat. Bottles, mugs, helmets, and other round or irregular items are often difficult to decorate with traditional methods. UV printing on curved surfaces solves this problem and gives you more options for customization.

What Makes UV Printing Different?

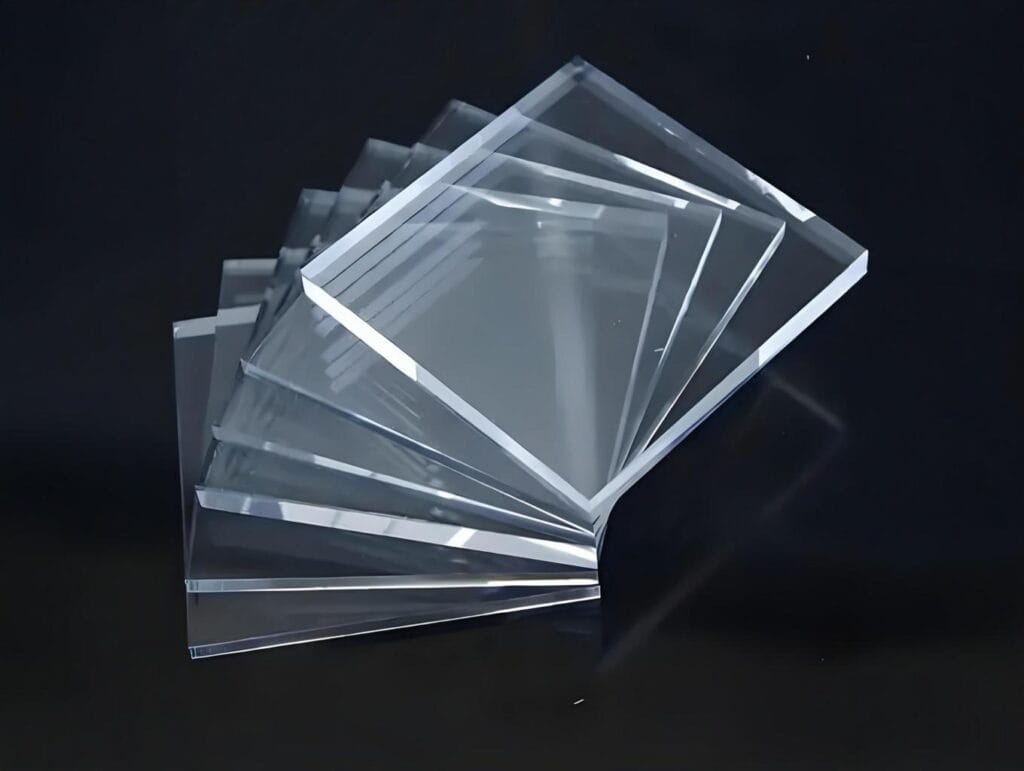

UV printers use special UV inks that are cured instantly with ultraviolet light. When combined with a rotary attachment, the machine can print smoothly on curved objects without distortion. The result is a bright, durable design that looks professional and lasts for a long time.

Main advantages:

Clear and detailed images even on round shapes

Works on glass, plastic, metal, ceramic, and more

Prints that resist scratches and fading

Where Can It Be Used?

Many industries now use curved-surface UV printing:

Drinkware – Custom logos on mugs, tumblers, and water bottles

Packaging – Branding for cosmetic or food containers

Sports gear – Team logos on helmets or balls

Industrial parts – Marking or serial numbers on irregular shapes

How the Process Works

The curved item is fixed onto a rotary fixture inside the printer. As the printer head moves, the fixture turns the object, so the ink is applied evenly all around. The curing light hardens the ink instantly, so the product is ready for use right after printing.

For example, our A3+ (3360) UV Printer (CH04) comes with a rotary attachment option, making it easy to handle curved-surface printing on bottles, mugs, and other cylindrical products. It delivers sharp details, full-color prints, and consistent results, whether you’re printing on flat boards or round objects.

Why It’s Good for Your Business

Accepts small or large orders

Fast production speed

Expands your product range without extra complex equipment

If you want to add more value to your products and attract customers who need personalization, UV printing on curved surfaces is a smart choice. It’s fast, flexible, and can turn a plain item into something unique.