Personalized gifts are a growing market, from custom phone cases to engraved plaques and printed mugs. UV flatbed printers have become a key tool for small factories and workshops because they can print directly on a wide range of materials with high quality and flexibility. Here are some real-world applications and insights.

Custom Phone Cases and Accessories

Many small shops use UV flatbed printers to produce personalized phone cases, laptop covers, and headphones. With direct-to-object printing, you can print full-color images, logos, or even short text directly onto curved or flat surfaces.

Practical tip: Use a template for alignment to reduce setup time and avoid misprints when switching between different phone models.

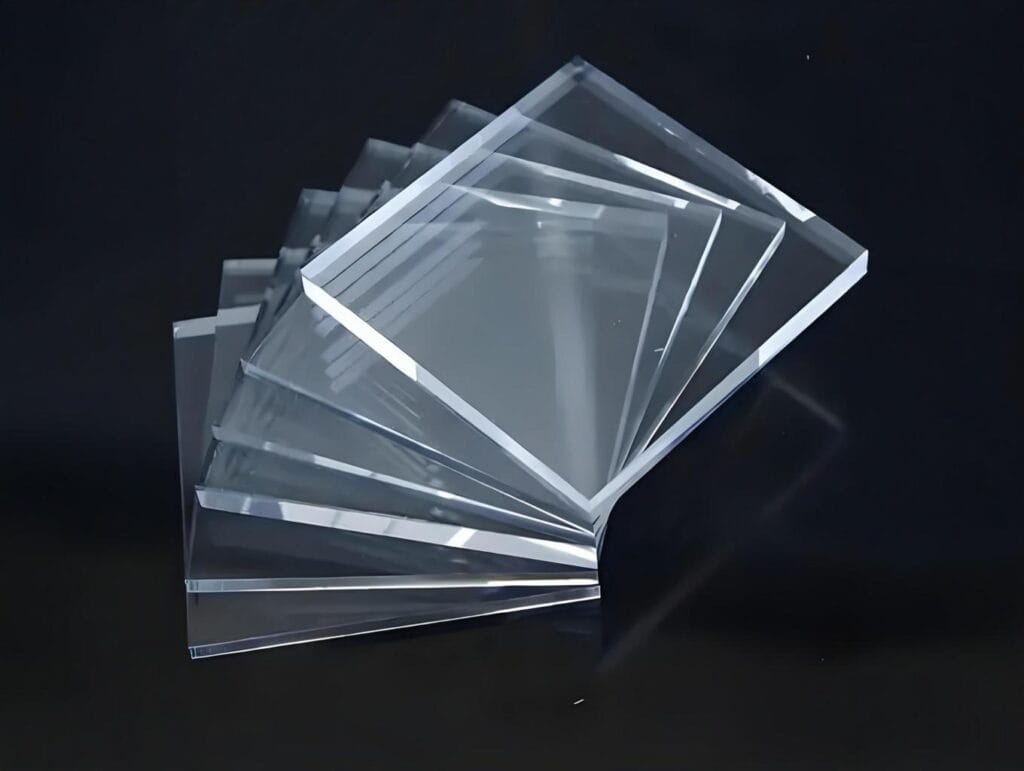

Engraved or Printed Plaques and Awards

UV flatbed printers can print on acrylic, wood, or metal plaques. They allow full-color logos and text, sometimes combined with white ink for contrast. Compared to traditional engraving, this method is faster and easier to customize for each order.

Practical tip: Batch similar plaque sizes together to reduce adjustment time and maintain consistent quality.

Mugs, Tumblers, and Drinkware

With specialized jigs, UV flatbed printers can print on mugs, tumblers, and bottles. This is popular for corporate gifts or event giveaways. You can combine custom graphics with seasonal designs for small batch production.

Practical tip: Check curing and ink adhesion carefully to prevent smudging, especially on curved surfaces.

Small Decor Items and Promotional Products

Items like coasters, keychains, ornaments, or photo frames can be produced quickly with UV flatbed printing. Because the printer can handle different materials without pre-treatment, short-run personalized orders are much easier to fulfill.

Practical tip: Keep common substrates and colors in stock for faster turnaround on custom requests.

Workflow Optimization Makes Small Orders Profitable

Even for small gift batches, efficiency matters. Using templates, automated height detection, and batch printing strategies ensures each job is consistent and reduces waste. This is especially important for shops handling dozens of unique custom orders per week.

The Bottom Line

UV flatbed printers enable small factories and workshops to produce high-quality personalized gifts efficiently. The combination of direct printing, material versatility, and fast setup makes short runs and small orders profitable while maintaining customization and quality.