UV printing has gained significant traction in industries ranging from promotional products to industrial applications due to its ability to print on a wide variety of materials with high-quality, durable results. Whether you’re in the signage, packaging, or custom product business, understanding the materials that can be used with UV printers is key to unlocking their full potential. This article explores some of the most popular materials for UV printing and how they can help elevate your products.

What is UV Printing?

Before diving into the materials, let’s quickly review what UV printing is and why it’s so effective. UV printing uses ultraviolet light to cure or dry the ink as it is printed. Unlike traditional printing, which relies on heat or air to dry the ink, UV printing instantly cures the ink using UV light, allowing for faster production times and the ability to print on a wide range of surfaces.

UV printers use special inks that are sensitive to ultraviolet light, enabling them to print on non-porous surfaces with remarkable detail and precision. This method is known for its efficiency, eco-friendliness, and ability to produce vibrant, long-lasting prints.

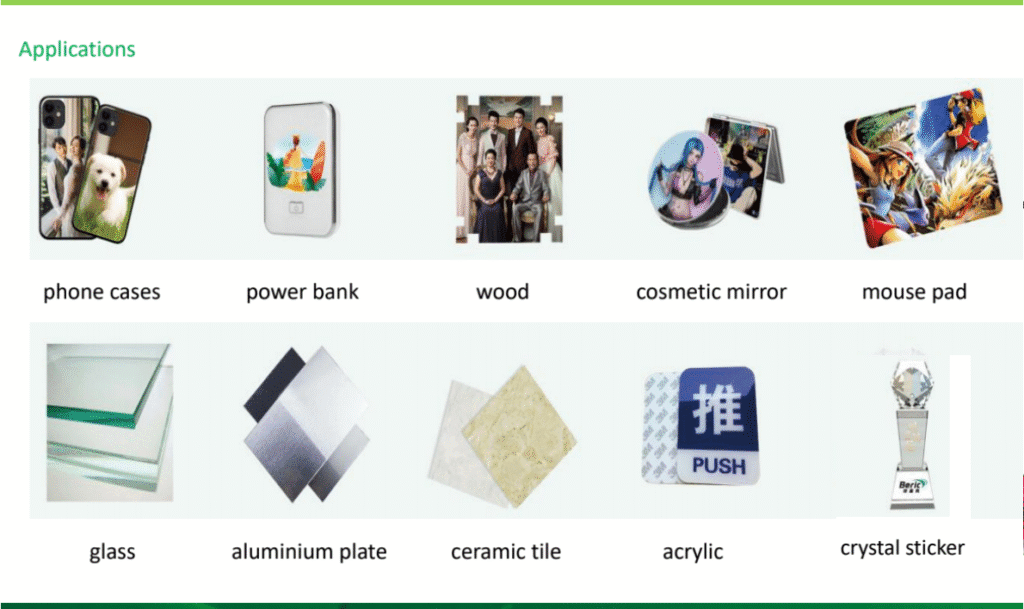

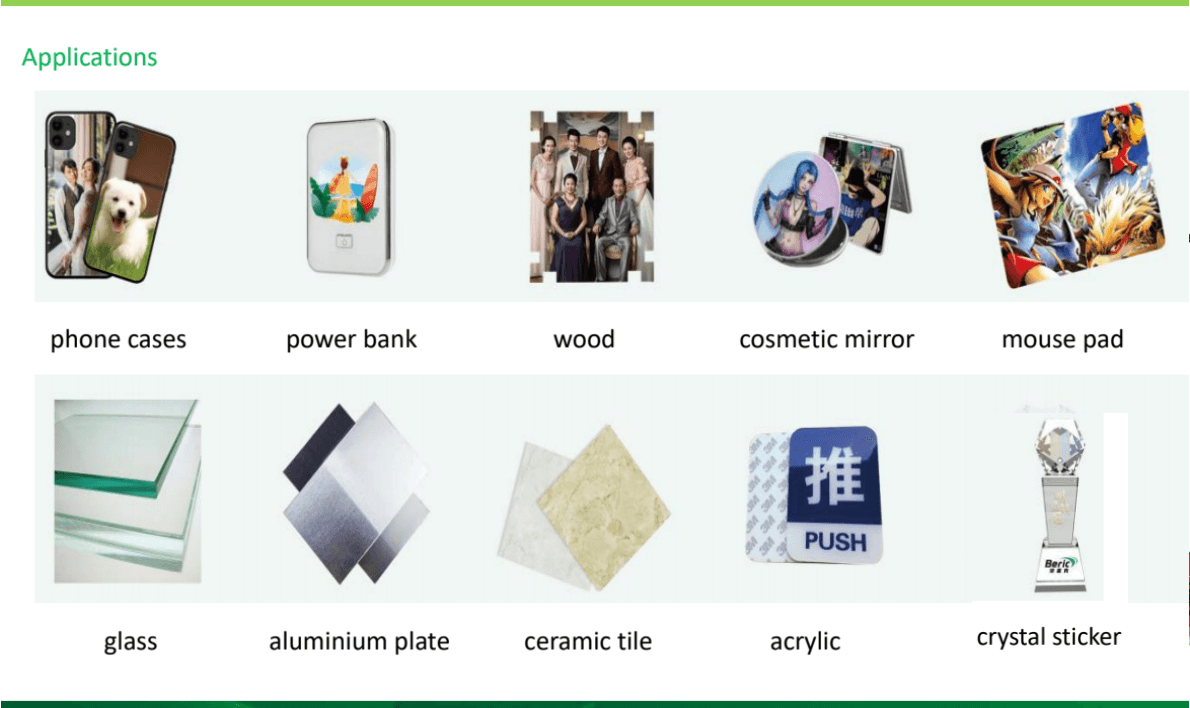

Popular Materials for UV Printing

Now, let’s take a closer look at the materials that are commonly used in UV printing. Each material offers unique advantages and applications, and UV printing helps to bring out the best in each one.

1. Plastic

Plastic is one of the most versatile materials for UV printing, as it provides a smooth, non-porous surface that allows UV inks to adhere well. Popular plastics used for UV printing include:

Acrylic: Acrylic sheets are commonly used for signage, displays, and awards. UV printing on acrylic creates glossy, vibrant finishes, ideal for custom promotional items or decorative pieces.

Polycarbonate: This durable plastic is often used for labels, automotive parts, and protective covers. UV printing on polycarbonate ensures prints are resistant to wear and tear, making them perfect for products that will be exposed to tough conditions.

PVC: PVC is commonly used for indoor signage, custom products, and nameplates. It’s an affordable option that still delivers high-quality prints when UV printed.

2. Wood

Wood is a popular material for personalized gifts, custom furniture, and home décor. UV printing on wood creates rich, vibrant designs that can be customized for a variety of applications. While wood is porous, it can still be printed on effectively with UV ink after a proper surface coating.

Whether you’re working with raw wood or pre-finished surfaces, UV printing ensures durable, high-quality results. Personalized wooden signs, photo frames, and furniture pieces are just a few examples of products that benefit from UV printing.

3. Glass

Glass is another material that benefits greatly from UV printing. Whether it’s custom mugs, decorative tiles, or glass signage, UV printing allows for precise, high-quality designs that are both vibrant and long-lasting. The non-porous surface of glass ensures that the prints are crisp and resistant to smudging or fading.

UV printing on glass is ideal for both transparent and opaque designs, allowing for full customization of products like awards, decorative glass panels, and even window signage. Its durability makes it a popular choice for both consumer and commercial applications.

4. Metal

Metal is a highly durable material and is often used in industrial applications such as signage, custom tools, and promotional products. Common metals used for UV printing include:

Aluminum: Aluminum is lightweight yet strong, making it a popular choice for custom signs, nameplates, and branding materials. UV printing on aluminum ensures sharp, colorful designs that last.

Stainless Steel: Stainless steel is ideal for industrial parts and products that need to withstand harsh conditions. UV printing on stainless steel offers enhanced durability and resistance to abrasion, corrosion, and fading.

UV printing on metal is especially beneficial for creating high-end promotional products, industrial labels, and custom nameplates, providing long-lasting results that can withstand both indoor and outdoor environments.

5. Textiles and Fabrics

While UV printing is often associated with non-porous materials, it can also be used on fabrics, providing an innovative way to create custom clothing, bags, and accessories. Textiles that can be UV printed include:

Cotton: Cotton garments can be printed with UV inks to create vibrant, custom designs that are durable and resistant to fading. UV printing on cotton is perfect for custom T-shirts, hats, and other apparel items.

Polyester: Polyester fabrics are well-suited for UV printing, as the smooth surface allows for high-quality, detailed prints that cure quickly under UV light. Polyester is commonly used for promotional items like custom bags, cushions, and sportswear.

UV printing on textiles offers the advantage of high color vibrancy and fine detail, which makes it perfect for personalized clothing, home décor, and promotional items.

6. Ceramics

Ceramics, such as mugs, tiles, and decorative plates, are another material well-suited for UV printing. UV inks adhere to the smooth, non-porous surface of ceramics, creating vibrant and durable designs.

Custom ceramic mugs, tiles for home décor, and promotional ceramic items are all popular products for UV printing. The prints are not only sharp but also resistant to fading, scratches, and water damage, making them perfect for products that will see regular use.

7. Leather

Leather is a premium material often used for custom items such as wallets, belts, and bags. UV printing on leather allows for intricate designs and logos to be printed without compromising the material’s texture.

Whether it’s a custom-engraved leather wallet or a branded leather belt, UV printing offers an excellent solution for producing high-quality designs that will last. The ability to print directly onto leather gives businesses more flexibility in customizing their products.

8. Paper and Cardboard

UV printing is not limited to just hard surfaces; it can also be used on paper and cardboard, especially in packaging and promotional printing. The benefit of using UV printing for paper and cardboard is the fast curing time, vibrant color, and resistance to moisture and wear.

Common applications include printed brochures, custom packaging, business cards, and event invitations. UV inks dry instantly, so there’s no risk of smudging, and the colors are rich and crisp, making your printed materials stand out.

Benefits of UV Printing on Different Materials

UV printing offers a wide array of benefits, including:

Fast Drying Times: UV inks cure instantly when exposed to UV light, which means your printed products are ready to handle right away.

Durability: UV printed designs are highly resistant to fading, scratches, and moisture, ensuring long-lasting results.

High-Quality Prints: UV printing produces sharp, vibrant colors and fine details, even on challenging surfaces like plastics, metals, and glass.

Eco-Friendly: UV inks release fewer volatile organic compounds (VOCs) compared to traditional inks, making UV printing a more environmentally friendly option.

UV printing offers incredible versatility across a wide range of materials, from plastics and metals to textiles and ceramics. Understanding which materials are compatible with UV printing allows businesses to tap into the full potential of this technology, whether they’re creating custom gifts, promotional items, or industrial products.

With its fast drying times, vibrant color output, and durability, UV printing is a powerful tool that can help companies differentiate their products in a competitive market. As UV printing technology continues to evolve, there will be even more exciting possibilities for customization, making it a must-have for businesses in a variety of industries.